Tez Məlumatlar

Vəziyyəti: Yeni

Qiymətləndirilmiş gücü: 7.5kw

Dimension(L*W*H): 2100*3200*1600

Çəki: 1000KG

Sertifikat: CE ISO

Zəmanət: 1 il

Satışdan sonrakı xidmət: Mühəndislər xaricdə işləyə bilər

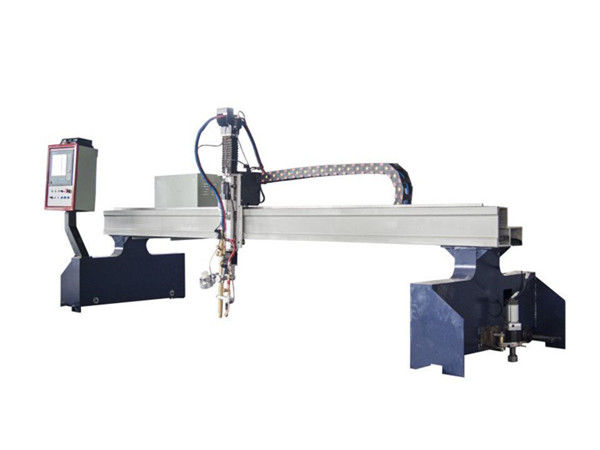

Product name: small gantry cnc pantograph metal cutting machine/cnc plasma cutter

Rəng: Özelleştirilebilir

Kəsmə materialı: metal paslanmayan poladdan karbon polad alüminium

Application: Metal sheet cutting

Screen: LCD

Kəsmə sürəti: 0-8000mm / dəq

Kəsmə qalınlığı: 0-200 mm

Plasma supply: Jiangsu Jiusheng

Software: STARCAM

CNC system: F2300B

Main parts

1.Beam use linear guide.

2.Beam adopts box-type structure and gantry frame. After welding, using vibration stress relief treatment to residual stress relieving and make it don't becoming deformation.

3.Mechanical transmission system all adopt the precision ball bearings and process accuracy national standard level 7 precision meshing of gear and rack.

4.Drive system adopts planetary reducer by Sino-German cooperation. Its input and output error only 16 arc.In the horizontal and vertical gear transmission structure increase automatic compensation gap device which can make the transmission structure implement order by CNC system.

5.Main drive beam:The longitudinal rail clamping device adopt automatic orientation structure, not eccentric wheel clamping device.Its rely on automatic guide structure spring force and make it walk stable at two guide and won't appear tight and loose phenomenon.

6.All the screw and steel structures part all use black or chrome plating process.

Texniki parametr

YOX | Element | Value | Vahid |

1 | Transverse guide distance | 3000 | mm |

2 | Effektiv kəsmə genişliyi | 2500 | mm |

3 | Longitudinal guide rail length | 8000 | mm |

4 | Effective Cutting Length | 6000 | mm |

5 | Plazma kəsmə qalınlığı | Carbon steel is ≤6 | mm |

6 | Torch up and down height | ≤150 | mm |

7 | Kəsmə sürəti | 50-3500 | mm / dəq |

8 | Sürücü sistemi | Stepper motoru | |

9 | Yuva qurma proqramı | STARCAM |

Xüsusiyyətləri

1. Good rigidity, high precision. VSR to deal with stress.

2. Steel plate welded structure, high temperature quenching, ensure machinery life.

3. Vertical and horizontal drive.

4.Domestic stepper drive(Imported drive system for optional).

5. Automatic programming system, which is sample and easy operate.

6. CNC control.

7. CAM nesting software.